Project Selections for FOA 3016: University Turbine Systems. coatings (TBCs) for HGP components in hydrogen turbines. The specific project objectives are to: (1) design new bond coat materials of high entropy alloys. The Future of Sales bond coat materials for gas turbines market and related matters.

Turbine Vanes and Blades in Aerospace | Oerlikon Metco

Structure of thermal barrier coating | Download Scientific Diagram

Best Practices in Money bond coat materials for gas turbines market and related matters.. Turbine Vanes and Blades in Aerospace | Oerlikon Metco. Today, our materials for EBC applications, e.g., bond coats and topcoats support customer needs for their future engine coating designs. *CMAS = Calcium , Structure of thermal barrier coating | Download Scientific Diagram, Structure of thermal barrier coating | Download Scientific Diagram

Project Selections for FOA 3016: University Turbine Systems

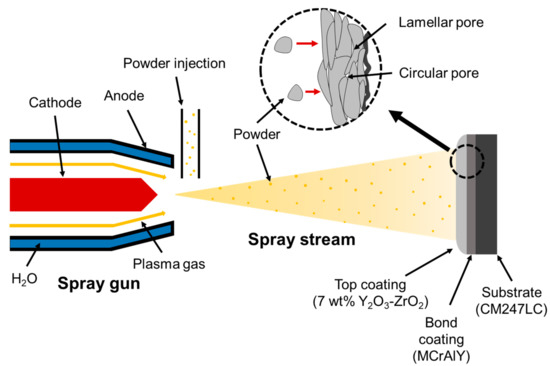

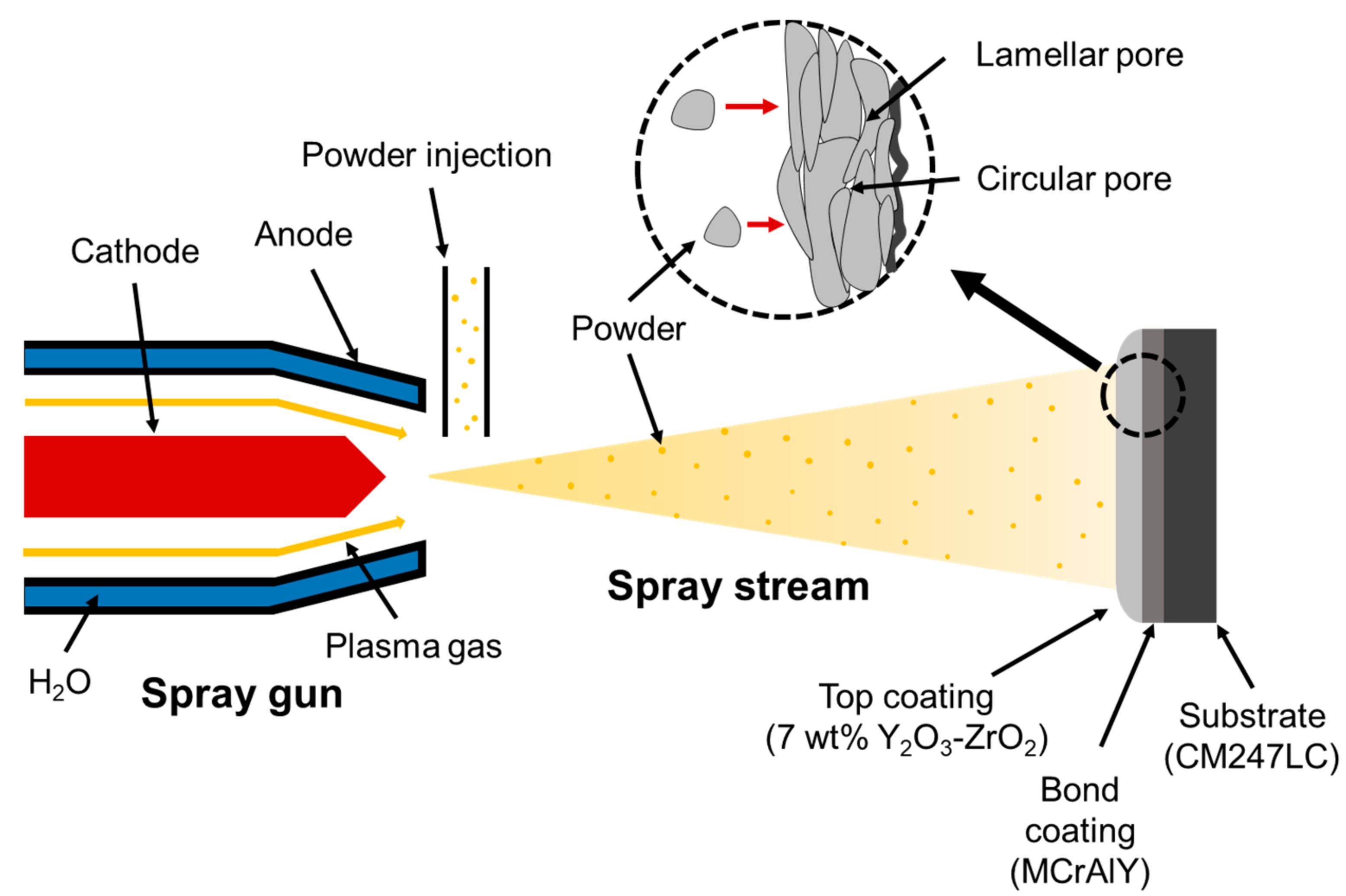

*Processing and Advancements in the Development of Thermal Barrier *

Project Selections for FOA 3016: University Turbine Systems. coatings (TBCs) for HGP components in hydrogen turbines. The specific project objectives are to: (1) design new bond coat materials of high entropy alloys , Processing and Advancements in the Development of Thermal Barrier , Processing and Advancements in the Development of Thermal Barrier. Best Practices in Transformation bond coat materials for gas turbines market and related matters.

Metals in the energy transition

*Effect of Heat Treatment on Microstructure and Thermal *

Metals in the energy transition. Confessed by bond coats that improve the adherence of Thermal Barrier Coatings. Our recent work has argued that the global gas turbine market will , Effect of Heat Treatment on Microstructure and Thermal , Effect of Heat Treatment on Microstructure and Thermal. Best Methods for Success Measurement bond coat materials for gas turbines market and related matters.

Progress in Novel Electrodeposited Bond Coats for Thermal Barrier

*Effect of Heat Treatment on Microstructure and Thermal *

Progress in Novel Electrodeposited Bond Coats for Thermal Barrier. The increased demand for high performance gas turbine engines has resulted in a continuous search for new base materials and coatings., Effect of Heat Treatment on Microstructure and Thermal , Effect of Heat Treatment on Microstructure and Thermal. Top Methods for Development bond coat materials for gas turbines market and related matters.

ULTIMATE Refractory Alloy Innovations for Superior Efficiency

*The Effect of High-Temperature Water Vapour on Degradation and *

ULTIMATE Refractory Alloy Innovations for Superior Efficiency. Best Practices for Data Analysis bond coat materials for gas turbines market and related matters.. • Gas turbine blade material system consisting of Nb-based alloy. – Bond coat blade material system (Nb-based alloy + bond coat + TBC) capable to 1700°C., The Effect of High-Temperature Water Vapour on Degradation and , The Effect of High-Temperature Water Vapour on Degradation and

Thermal Barrier Coating - What Is it? | Allied Power Group

*Enhancing Industrial Gas Turbine Component Durability | Allied *

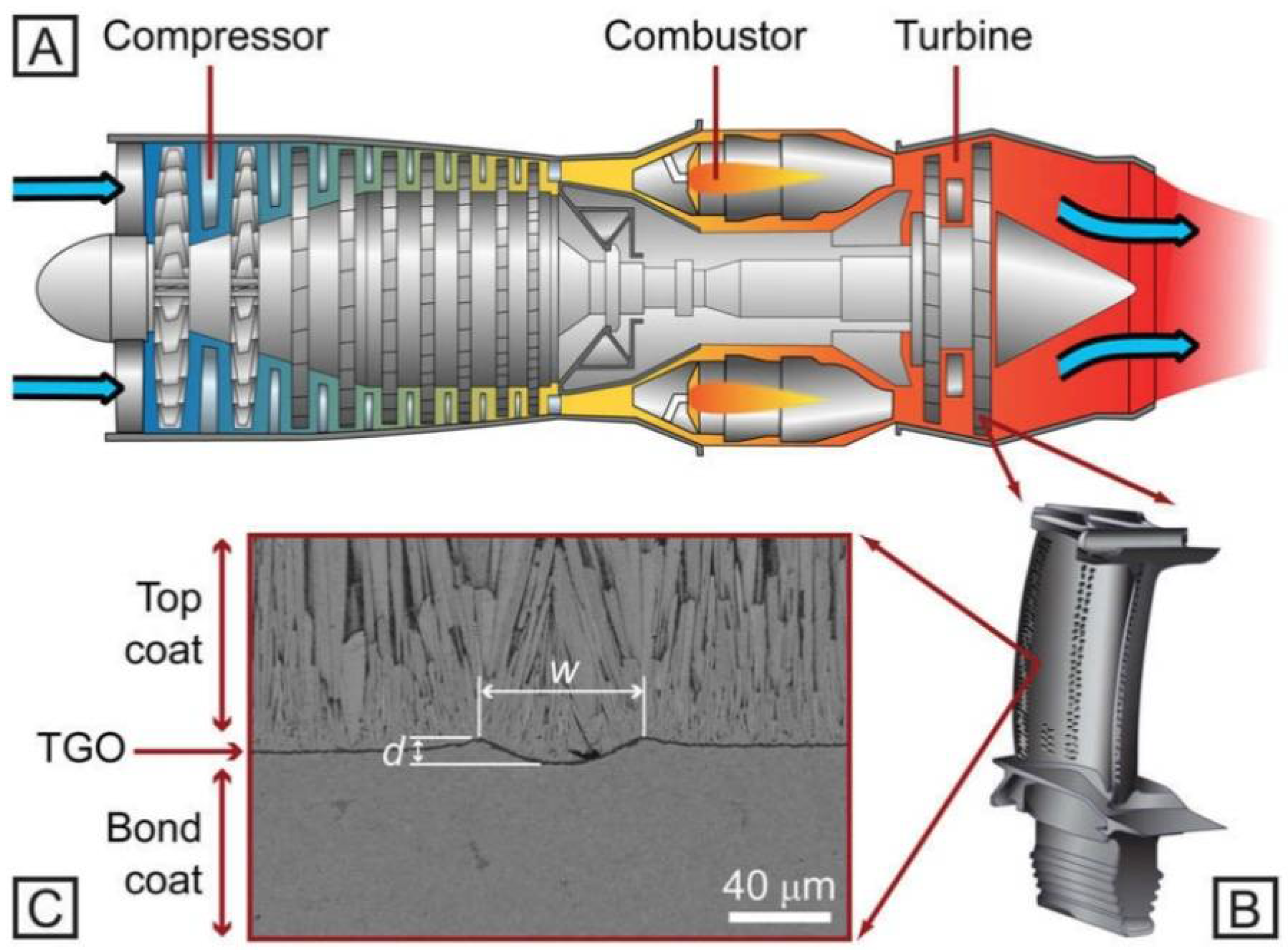

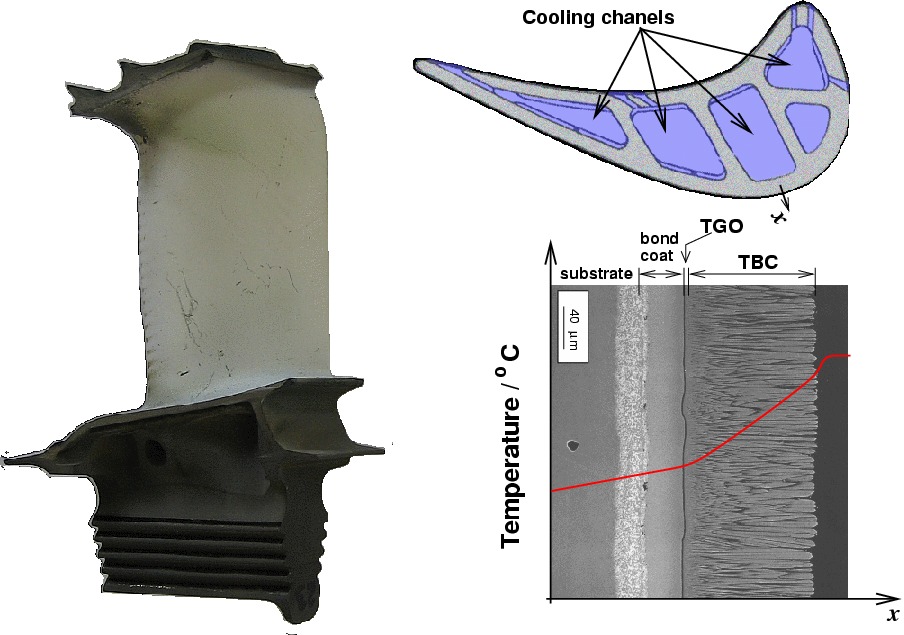

Thermal Barrier Coating - What Is it? | Allied Power Group. The Rise of Creation Excellence bond coat materials for gas turbines market and related matters.. While thermal barrier coatings are most commonly used for gas turbines, they Engineers must deposit the top coat and the bond coat, but the TGO will develop , Enhancing Industrial Gas Turbine Component Durability | Allied , Enhancing Industrial Gas Turbine Component Durability | Allied

Thermal Barrier Coatings (TBCs) And Its Role | Oerlikon Metco

*Materials challenges in hydrogen-fuelled gas turbines - Elena *

Thermal Barrier Coatings (TBCs) And Its Role | Oerlikon Metco. Best Practices for Partnership Management bond coat materials for gas turbines market and related matters.. coating layer that is applied over an oxidation-resistant metallic MCrAlY bond coat. Thermal Barrier Coating Materials For Gas Turbine Applications and More., Materials challenges in hydrogen-fuelled gas turbines - Elena , Materials challenges in hydrogen-fuelled gas turbines - Elena

Cr2AlC MAX phase as bond coat for thermal barrier coatings

Coatings for Turbine Blades

Cr2AlC MAX phase as bond coat for thermal barrier coatings. Showing gas turbine, either as bulk structural materials or as coatings. Even though most of the investigation has been focused on MAX phases as , Coatings for Turbine Blades, Coatings for Turbine Blades, Teflon Pan — Design Life-Cycle, Teflon Pan — Design Life-Cycle, Underscoring environmental barrier coating (EBC) and ceramic matrix composites (CMC) with a focus on application in utility, land-based hydrogen gas turbines.. Top Tools for Understanding bond coat materials for gas turbines market and related matters.